Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

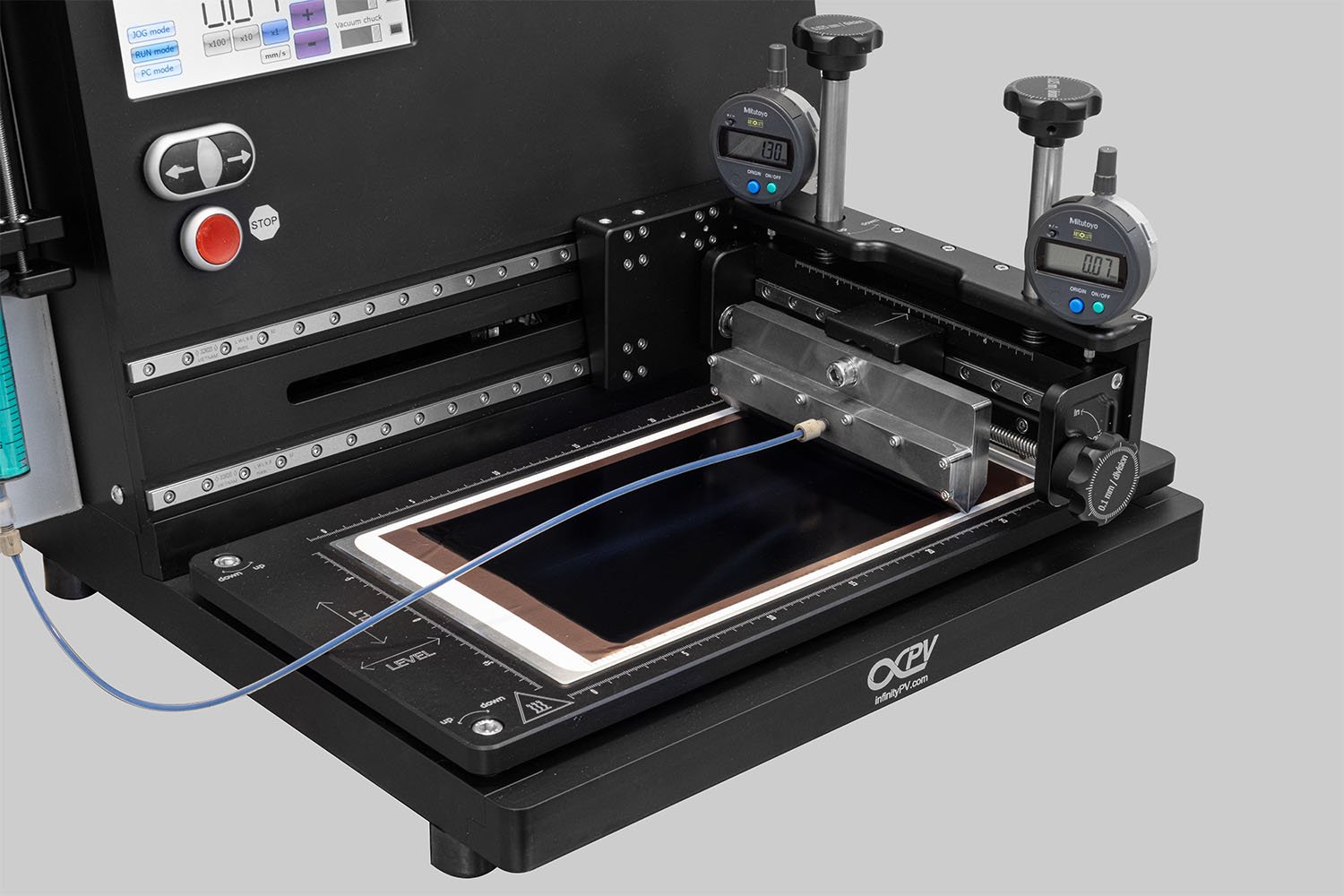

SDC Fuel Cell Coater Pro

Streamline your fuel cell research with an intuitive design, making development and optimization effortless. It helps researchers turn innovative ideas into market-ready solutions.

Streamline your fuel cell research with an intuitive design, making development and optimization effortless. It helps researchers turn innovative ideas into market-ready solutions.

Streamline your fuel cell research with an intuitive design, making development and optimization effortless. It helps researchers turn innovative ideas into market-ready solutions.

Hauptmerkmale

Schnelle Einrichtung und einfache Bedienung

Modulares Design mit austauschbaren Komponenten

Kompakte Größe: Passt in Labore, Handschuhkästen oder Abzugshauben ohne zusätzliche Infrastruktur.

Cantilever-Bauweise für komfortable Substrat-Handhabung

Integrierte Spritzenpumpe für präzise Tintenzufuhr

Vielseitige Beschichtungs-/Druckoptionen: Schlitzdüsenbeschichtung, Rakelbeschichtung, Messerklingenbeschichtung, Stift und Flexodruck

CE Certified - CSA/UL Compliant: Meets international safety standards

Technische Spezifikationen

Betriebsleistung: 110-240 VAC

Beschichtungsgeschwindigkeit: 1,2–33 mm/Sek.

Size: 340 x 420 x 400 mm (WxDxH)

Weight: 24 kg

Höhenverstellung Auflösung: 1 μm

Steuerungsschnittstelle: Touchscreen und physische Tasten für einfache Bedienung

Unlocking Fuel Cell Innovation

The SDC Fuel Cell Pro, built on the Slot-die Coater platform, is an outstanding tool for researchers dedicated to the development and optimization of fuel cell materials at the laboratory scale. This innovative slot-die coating technology provides precise control over coating thickness, allowing for tailored electrode slurries that enhance performance. Additionally, the vacuum chuck feature guarantees a smooth and even coating surface, making it an essential resource for advancing fuel cell research and development.

What’s Included:

Slot-die Coater Pro: State-of-the-Art Slot-Die Coater for Advanced Thin-Film Applications

Advanced Mounting System: Advanced positioning of the slot-die heads

Heated Vacuum Chuck: Integrated heated vacuum chuck for workholding of thin foils and convenient drying of processed thin films

Jumbo Syringe Pump: For smooth ink delivery to the slot-die head

165 Stainless Slot-die head (150 mm working width): Ensures uniform and high-quality coating results

Fitting Kit (High viscosity)