Laserstrahlinduzierter Strom (LBIC)

A desktop platform that offers rapid, high-resolution mapping of photovoltaic responses across expansive areas.

Ultrafast LBIC Mapping for Solar Cell Analysis

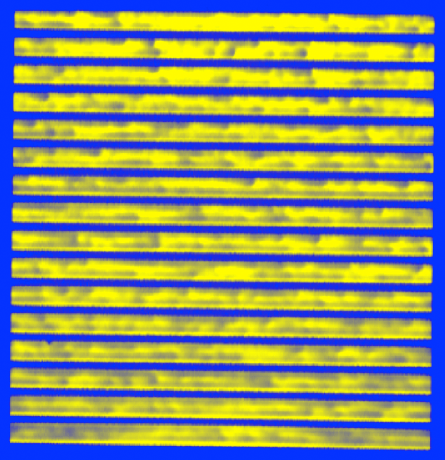

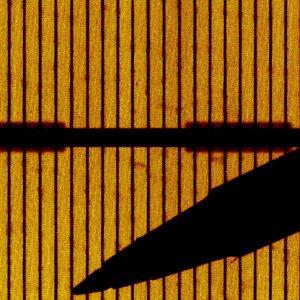

Ultrafast Laser Beam Induced Current (LBIC) mapping is performed using a laser spot with a diameter of 40 microns, modulated over a testing area of 250 x 250 mm². This method allows for the creation of detailed maps in just seconds. The practical resolution of the system is < 100 microns, depending on the surface of the solar cell.

Key Benefits of InfinityPV's LBIC Approach

InfinityPV’s LBIC system is inherently immune to noise, ensuring accurate results even in challenging conditions. It excels in mapping both concave and convex surfaces, making it an ideal solution for flexible solar cells. The turn-key system is controlled via the included infinityPV software, which features:

Auto Calibration

Active Area Calculation

Color Maps

Simple Scanning Area Selection

These features provide fast and easy imaging of any photovoltaic (PV) technology.

Wide Wavelength Range for Versatile Applications

With an accessible wavelength range of 400–1100 nm, this system is well-suited for mapping single junctions, tandem devices, and modules. Differences in junction ideality within a module may lead to variations in signal strength, but the system handles this with ease.

Defect Detection and Failure Analysis

LBIC maps generated by the infinityPV system allow for the easy identification of:

Defects

Coating Errors

Shunts

Inactive Photovoltaic Regions

Additionally, the system is ideal for identifying failure modes over time in solar cells and modules that have undergone accelerated ageing tests. It can highlight issues such as ingress of permeants and contact failures.

Technische Spezifikationen

Two Configurations: Available in Basic and Advanced models to suit various needs.

Ultra-High Mapping Speed: Allows for fast and efficient data collection.

Laser-Based Solar PV Response Mapping: Ensures precise mapping of photovoltaic responses using a laser.

Ideal for Quality Control & Defect Identification: Helps detect defects and assess material quality with high accuracy.

Active Area Determination: Useful for efficiency calculations by accurately determining the active area of solar cells.

High-Resolution Scan: Provides enhanced details for more precise analysis.

Laser Wavelength Range: From 400 nm to 1100 nm, offering flexibility in measurements.

Mapping Resolution: Less than 100 µm, with a 40 µm spot size for exceptional precision.

Testing Area: 250 x 250 mm², ideal for standard photovoltaic cell sizes.

User-Friendly Software: Intuitive interface for easy operation and data analysis.

Multi-Wavelength Support: Up to 4 wavelengths for more comprehensive analysis.

Light Bias: Offers light biasing capabilities to simulate real-world conditions.

Electrical Bias Option: Provides the option for electrical biasing during tests.

Turn-Key System: Complete, ready-to-use solution for immediate deployment.

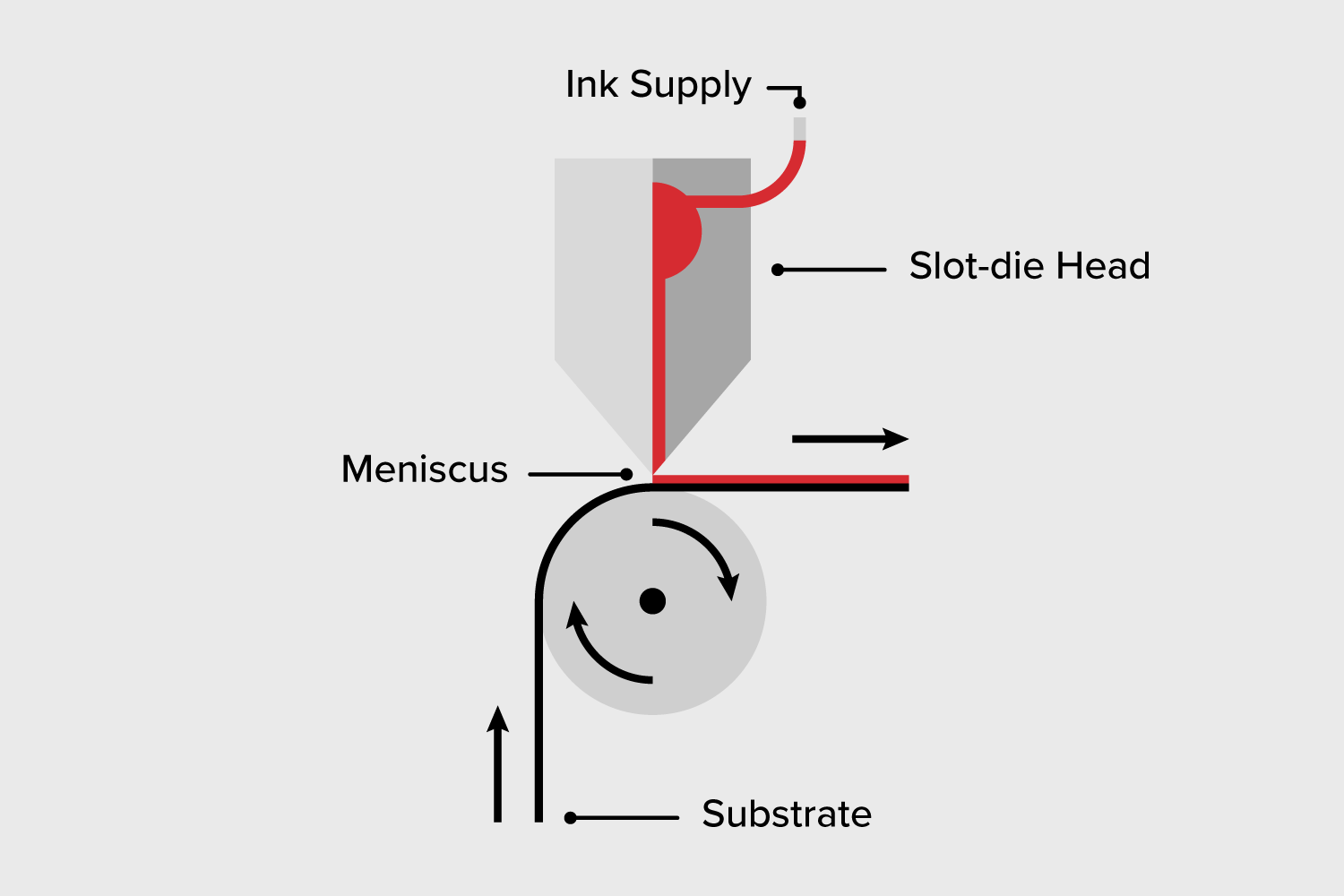

How Does the LBIC Work?

LBIC - Options and installation

The Professional LBIC comes in two different configurations: a Basic and an Advanced.

| Professional LBIC Basic | Professional LBIC Advanced | |

|---|---|---|

| Test area | 250 x 250 mm2 | 250 x 250 mm2 |

| Mapping resolution (µm) | <100 | <100 |

| Laser spot size | ~40 µm | ~40 µm |

| Laser Wavelength | 410 nm | 400 -1100 nm |

| Mapping speed | Seconds - minutes | Seconds - minutes |

| No. of lasers | 1 | Up to 4 |

| Field modulators | Yes | Yes |

| Preamplifiers | Yes | Yes |

| Light bias | No | Yes |

| Modulation of light source | No | Yes |

| Phasing of light sources | No | Yes – when 2 or more lasers |

| Electrical bias | Optional | Optional |

| EQE device and software | Optional | Optional |

| Laptop with infinityPV LBIC software | Yes | Yes |

LBIC - Videos

Professional LBIC

Economy LBIC, solar cell light beam induced current mapping by infinityPV

The Academic LBIC

Real-time degradation with LBIC

Meistern Sie die Rolle-zu-Rolle-Verarbeitung von gedruckten Solarzellen

Nehmen Sie an unserem praktischen Workshop für gedruckte Elektronik teil und sammeln Sie praktische Erfahrungen in jedem Schritt der Herstellung von gedruckten Solarzellen, von der Tintenaufbereitung bis zur Prüfung und abschließenden Integration. Sie beherrschen das Design, den Druck, die Beschichtung und die Leistungsprüfung von Solarzellen mit modernsten Geräten wie dem Laboratory Roll-to-Roll Coater, dem Slot-Die Coater, dem LBIC, dem ISOSun Solar Simulator und den Source Measure Units. Unsere Workshops sind auf Ihre Bedürfnisse zugeschnitten und eignen sich perfekt für Studenten, die ECTS-Punkte erwerben möchten, oder für Fachleute, die ihr Fachwissen erweitern möchten.