SpotTEC Corona-Oberflächenbehandlung

A corona surface treater used for treatment of profiles, treatment of cables and injection moulded parts.

Transform Your R2R Process With Corona Surface Treatment

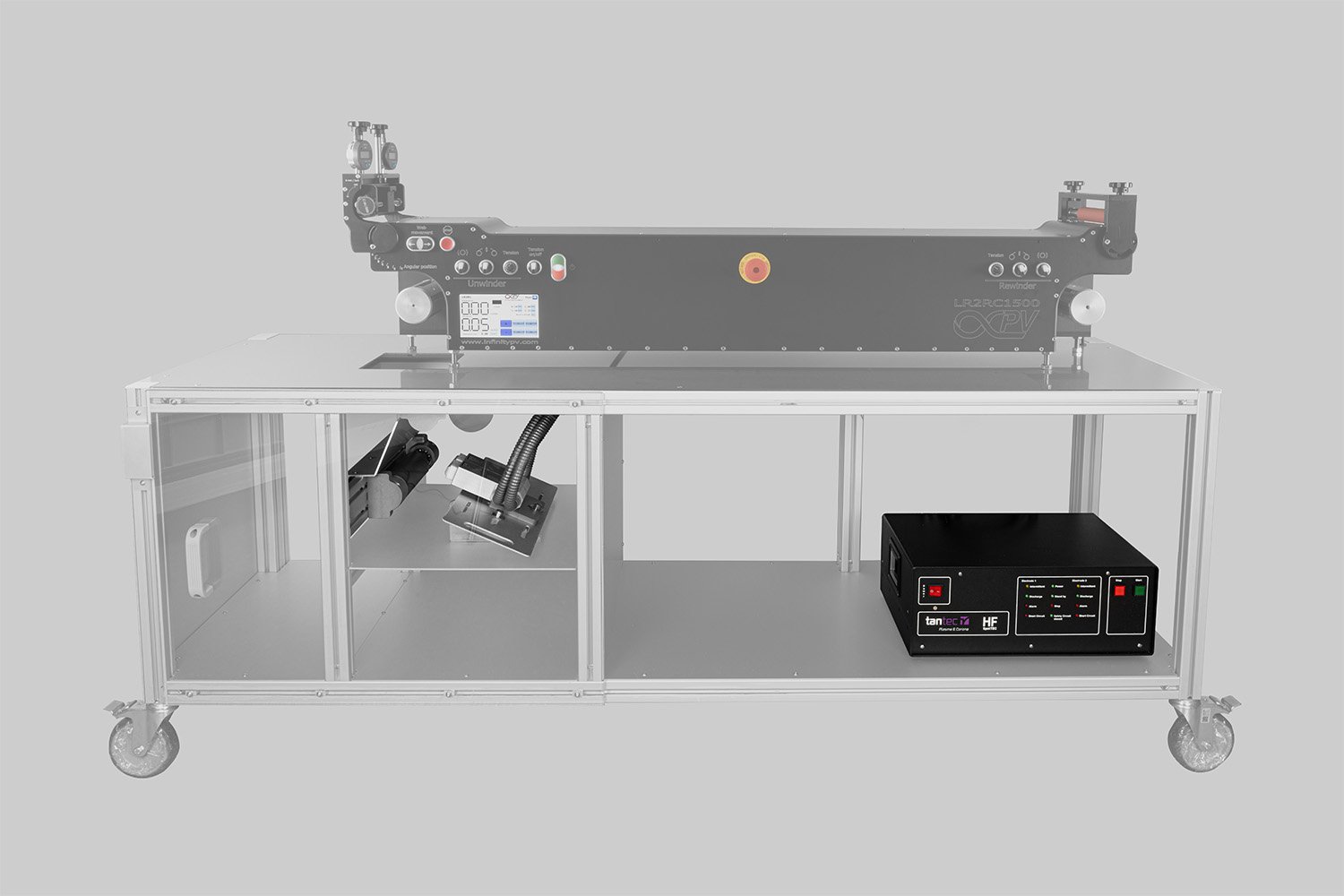

The SpotTEC Corona Surface Treater by Tantec is a powerful and adaptable machine, perfect for enhancing the Laboratory Roll-to-Roll Coater when surface treatment capabilities are needed. Ideal for treating profiles, cables, and injection-molded parts, the SpotTEC seamlessly integrates into production lines, bringing exceptional flexibility and efficiency to surface preparation.

Using high-voltage discharge in atmospheric air, the SpotTEC applies a high-frequency charge onto substrate surfaces, promoting strong adhesion for glue, inks, and coatings. Its advanced design eliminates the need for a counter electrode, with a blower precisely directing the discharge generated between two electrodes in the discharge head.

Providing a cost-effective solution for pre-treating three-dimensional, molded, or extruded plastic parts, the SpotTEC offers low investment and operational costs. Available in single or double electrode configurations and fully compliant with CE and EMC regulations, this versatile tool expands the Laboratory Roll-to-Roll Coater's capabilities, making it a go-to choice for a broad range of plastic surface treatment applications.

Hauptmerkmale

Effortless Installation and Use: No parameter adjustments are needed—simply connect to the mains, and you’re ready to go.

Low Maintenance: Maintenance is minimal, requiring only periodic replacement of the metal electrodes.

Flexible Configuration Options: The generator can be set up with either a single or dual treatment head for added versatility.

Airflow Monitoring: During operation, airflow is continuously monitored to ensure optimal performance.

LED Status Indicators: Front-panel LEDs provide real-time updates on the generator’s status throughout the treatment process.

Treatment Versatility: Designed to treat non-conductive surfaces at line speeds up to 20 m/min, offering effective performance at lower speeds.

The SpotTEC Corona Surface Treater

Technische Spezifikationen

| Technische Spezifikationen | SpotTEC Single | SpotTEC Dual | SpotTEC Discharge Head |

|---|---|---|---|

| Mains voltage and frequency | 115 or 230 VAC 50/60 Hz | 115 or 230 VAC 50/60 Hz | N/A |

| Output voltage/power | Voltage: 2 x 6.5 kV Power: 550 | Voltage: 2 x 6.5 kV Watt Power: 1100 Watt | N/A |

| Output frequency | Approx. 25 kHz | Approx. 25 kHz | N/A |

| Power consumption | Max. 600 VA | Max. 1100 VA | N/A |

| Dimensions in mm (LxWxH) | 500 x 485 x 195 (incl. connections) | 500 x 485 x 195 (incl. connections) | 60 x 40 x 160 (excl. connections) |

| Weight in kg | 13 (23 at 115 VAC) | 19 (29 at 115 VAC) | 1.7 (incl. hose) |

| Treatment width in mm | N/A | N/A | 45-65 mm |

| Treatment distance in mm | N/A | N/A | 5-20 mm |

| Treatment speed in m/min | N/A | N/A | Max. 20 m/min |

| Regulation compliance | CE – RoHs – WEEE | CE – RoHs – WEEE | CE – RoHs – WEEE |

Was ist Korona- und Plasma-Oberflächenbehandlung?

Explore the differences between corona and plasma surface treatment technologies, crucial for enhancing adhesion in industrial applications. Discover how these methods modify surface energy to combat dewetting, improve wettability, and ensure better bonding of inks, coatings, and adhesives on non-porous materials. Learn about their benefits, applications, and why surface treatment is essential for achieving optimal product quality and efficiency in manufacturing processes.

Broschüre herunterladen

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Video: Was ist der Laboratory Roll-to-Roll Coater?

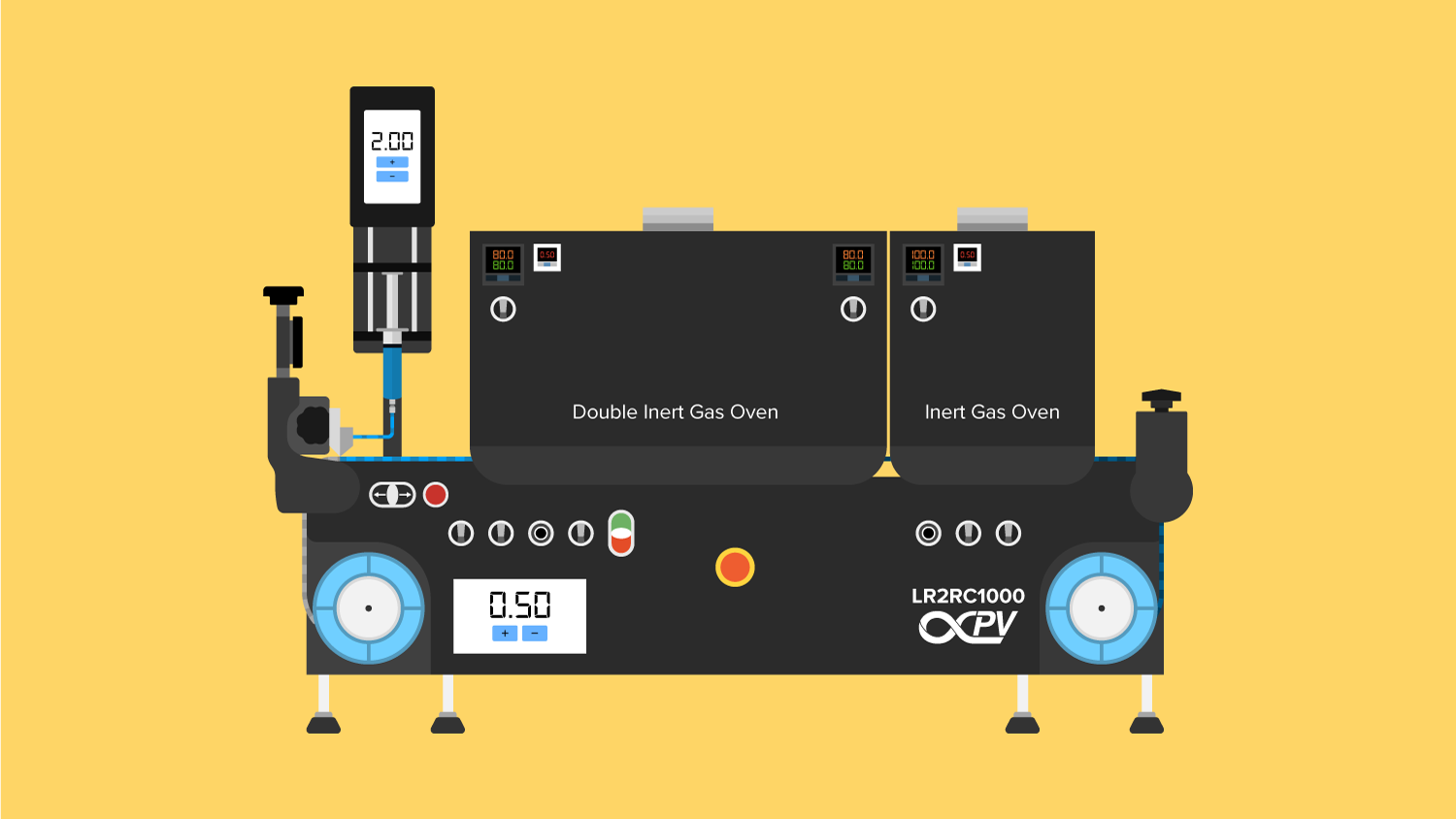

Die Labor-Roll-to-Roll-Beschichtungsanlage ist eine kompakte, hochpräzise Laborbeschichtungsanlage, die die Verarbeitung dünner Funktionsschichten revolutioniert. Sie bietet modulare Anpassungsmöglichkeiten für unterschiedliche Anforderungen, skalierbare Effizienz für die Produktion in kleinem Maßstab und ein benutzerfreundliches Design mit leicht abnehmbaren Komponenten. Ideal für Anwendungen wie Batterien, Brennstoffzellen und Solarzellen ermöglicht sie Ihnen die Anpassung eines Systems, das perfekt auf Ihre Bedürfnisse zugeschnitten ist.