Slurry-Coater

Precision Slurry Coating for Next-Generation Thin Films: Consistent Quality, Uniform Application.

Slurry Coating for Advanced Thin Film Production

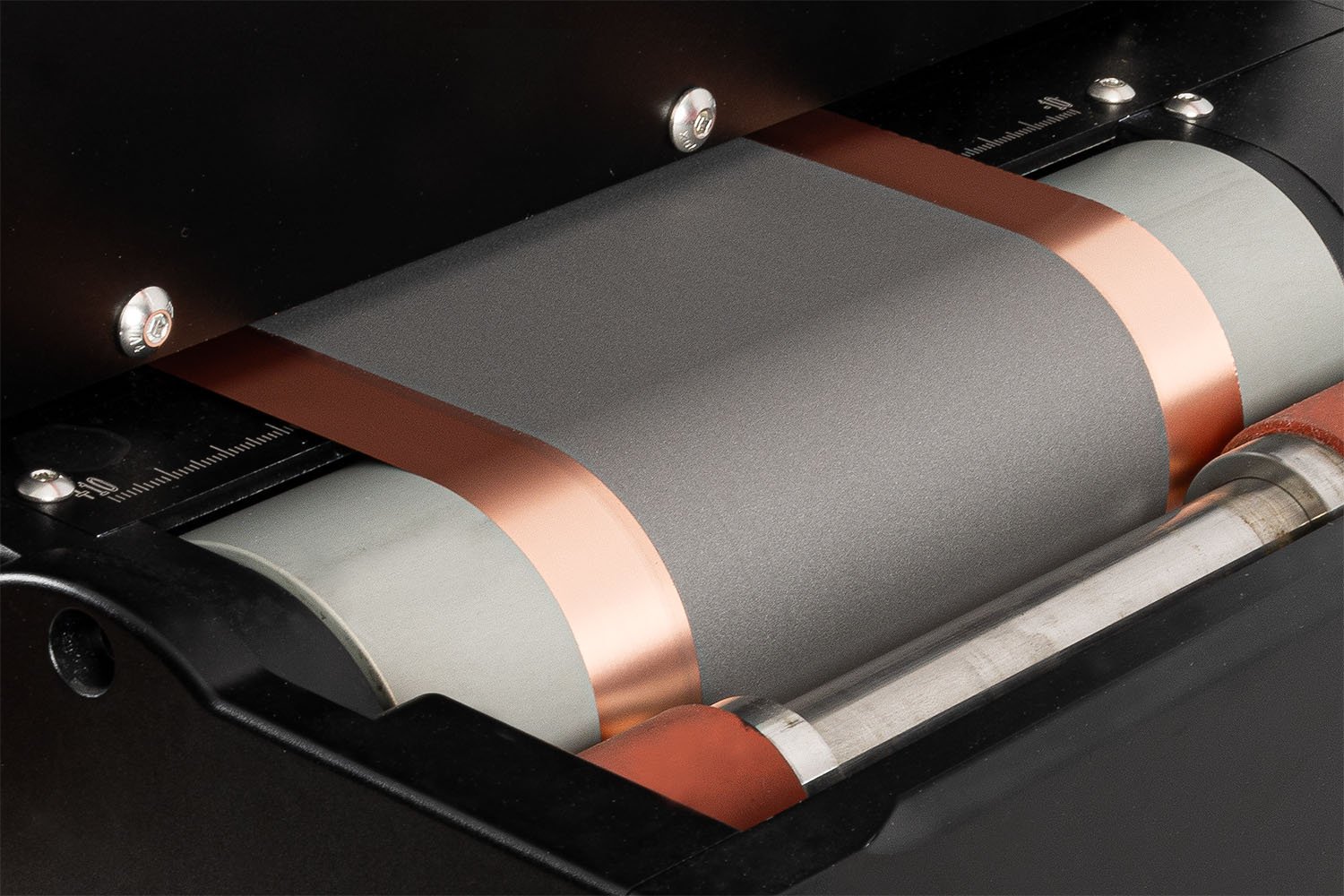

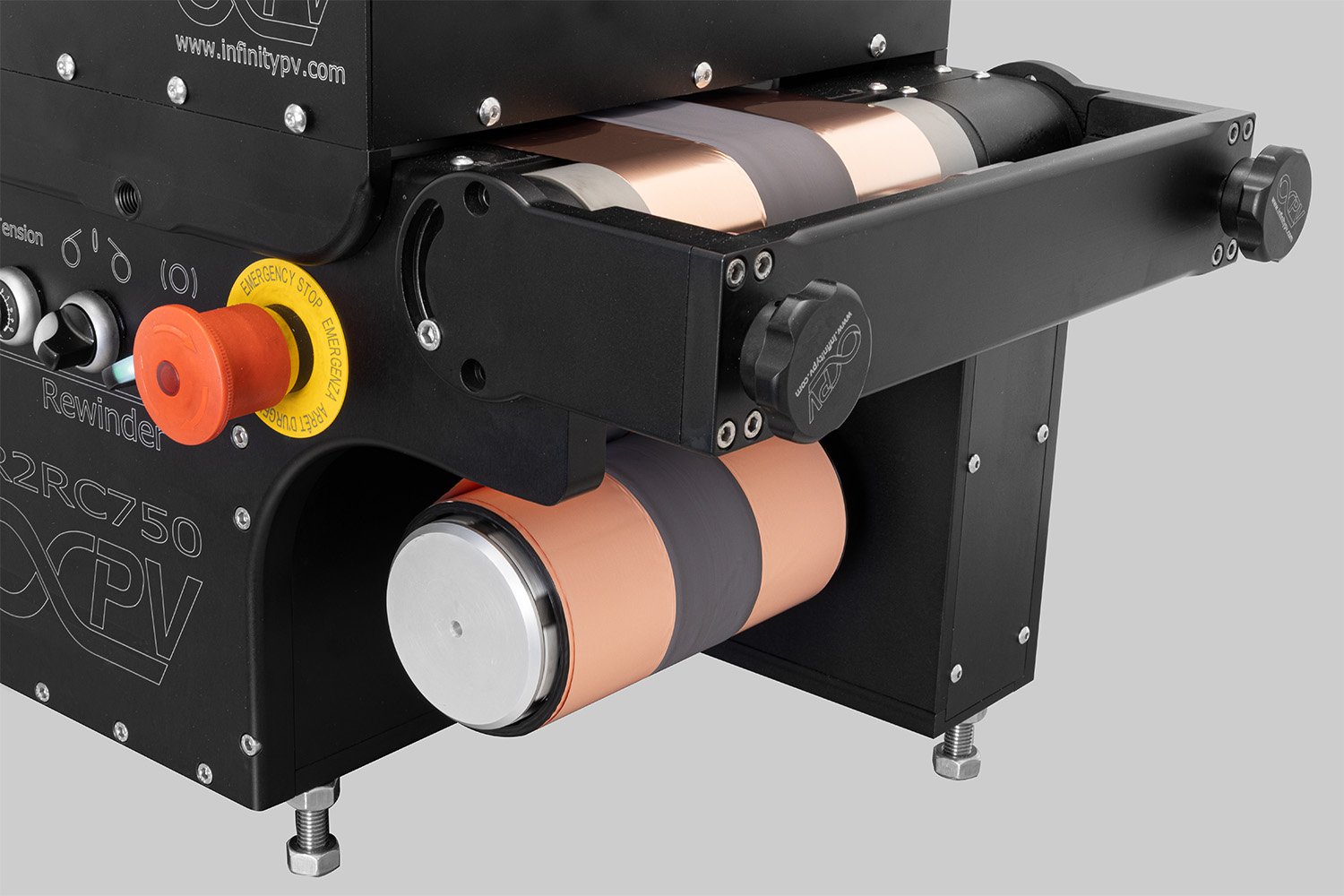

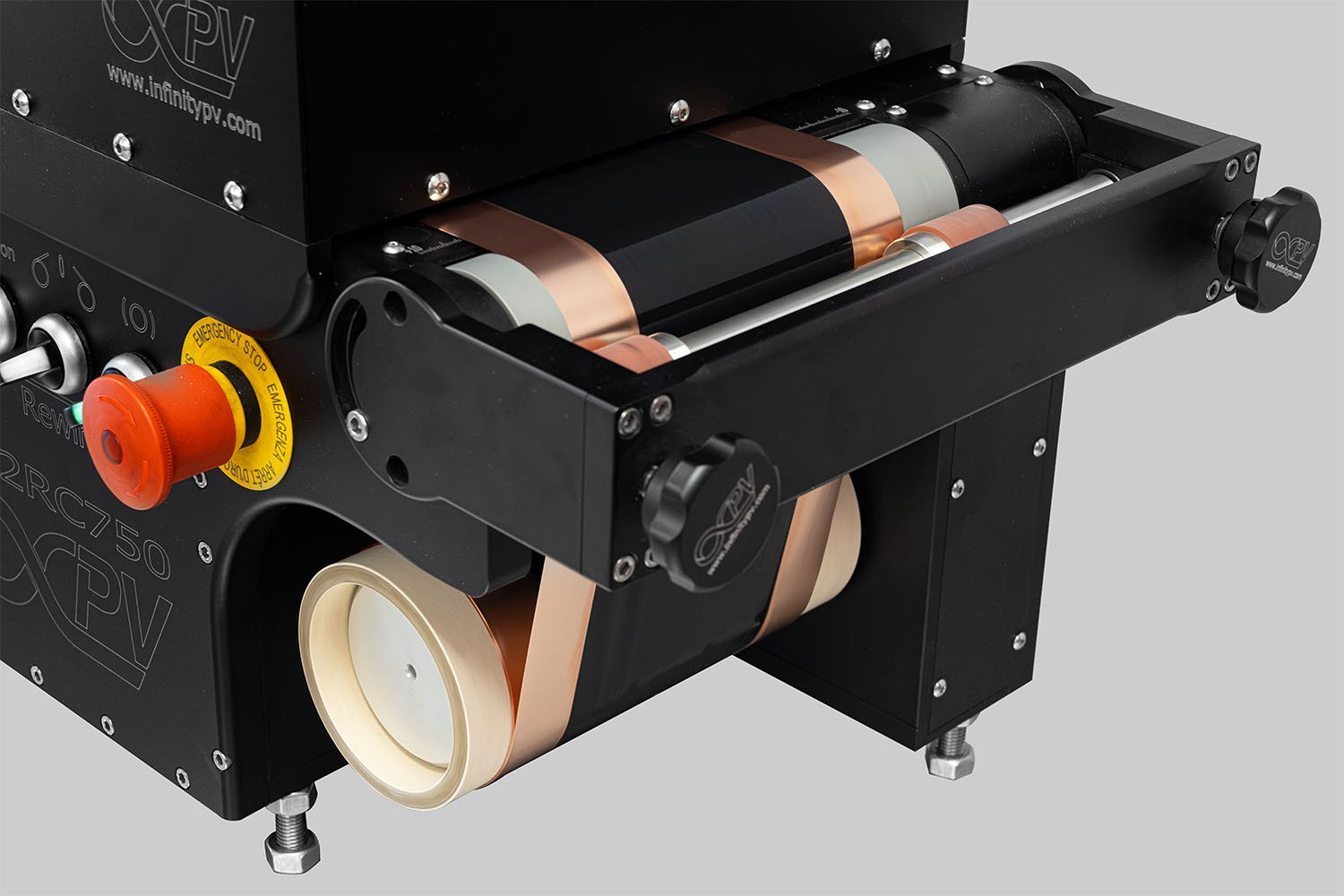

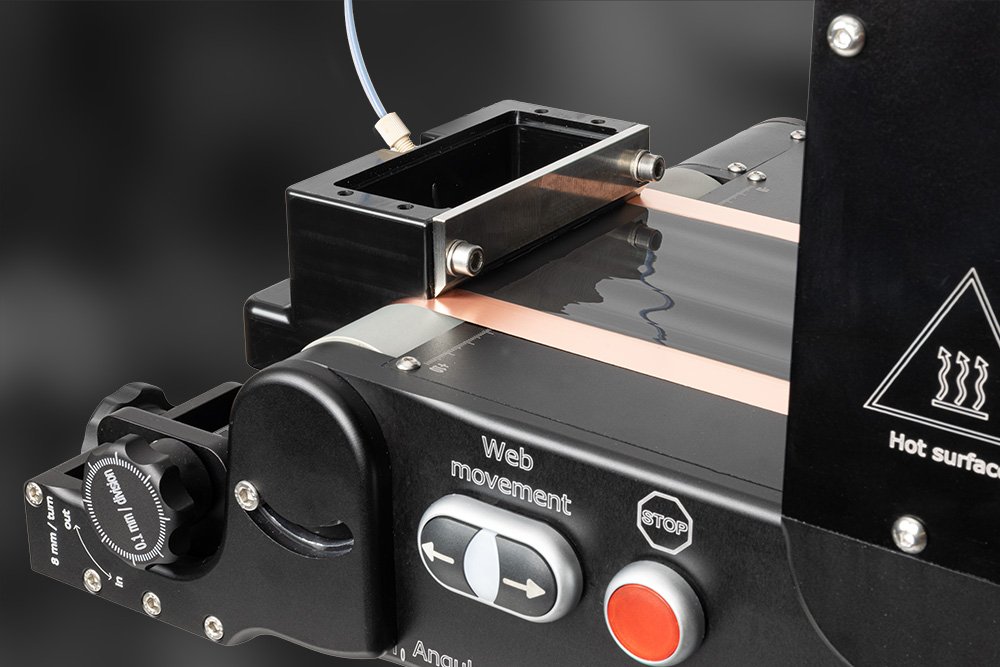

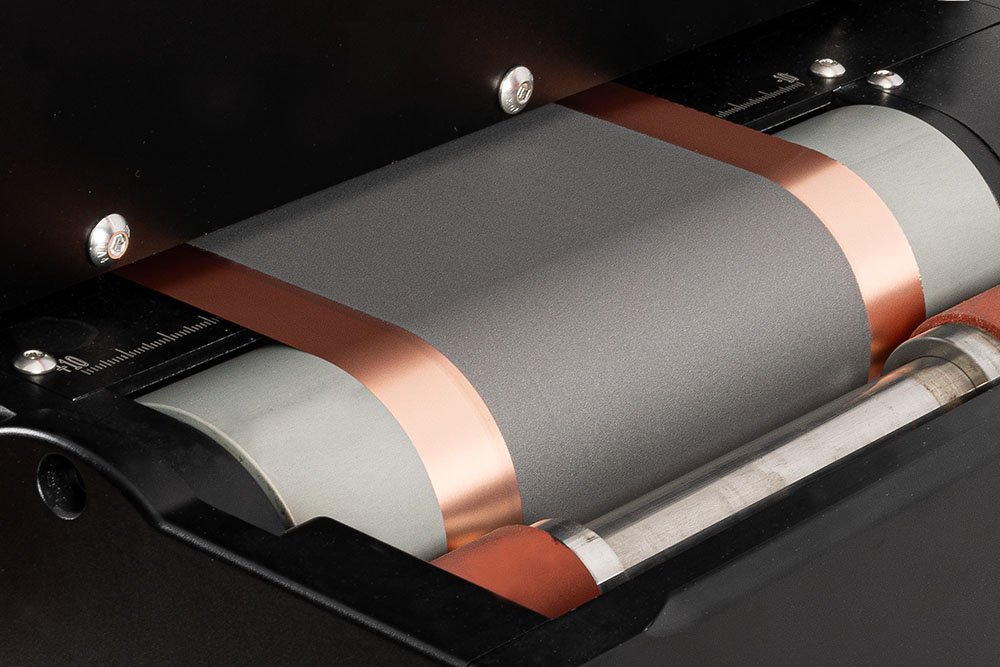

The Slurry Coater is a fundamental wet film forming tool for the Laboratory Roll-to-Roll Coater platform, enabling lab scale production of advanced functional thin films. This includes thin film batteries, fuel cells and printed solar cells. The Slurry Coater is used for applying a viscous mixture (ideal for non-newtonian liquids and suspensions) in the form of a slurry, accurately and uniformly, onto a substrate, ensuring consistent quality and performance. With continuous mixing of the slurry during processing, accomplished as the coating takes place over the backing roller of the Laboratory Roll-to-Roll Coater, sedimentation of particles in the ink is prevented. Dosing of ink can be controlled via the Laboratory Roll-to-Roll Coater pumping systems and it is possible to keep the ink under inert conditions.

Hauptmerkmale

Designed for Slurry Coating

Made from POM and Stainless Steel (316L)

100 mm Coating Width

Works With Thin Substrates (5-25 um)

Simple Adjustment of the Substrate - Knife Gap

Precise Ink Delivery from the Laboratory Roll-to-Roll Coater Pumping System

Option for Inert Conditions

Slurry Coater für die gleichmäßige Nassfilmbeschichtung im Labormaßstab

How Does the Slurry Coater Work?

The Slurry Coater is a fundamental wet film forming tool for the Laboratory Roll-to-Roll Coater platform enabling lab scale production of advanced functional thin films.

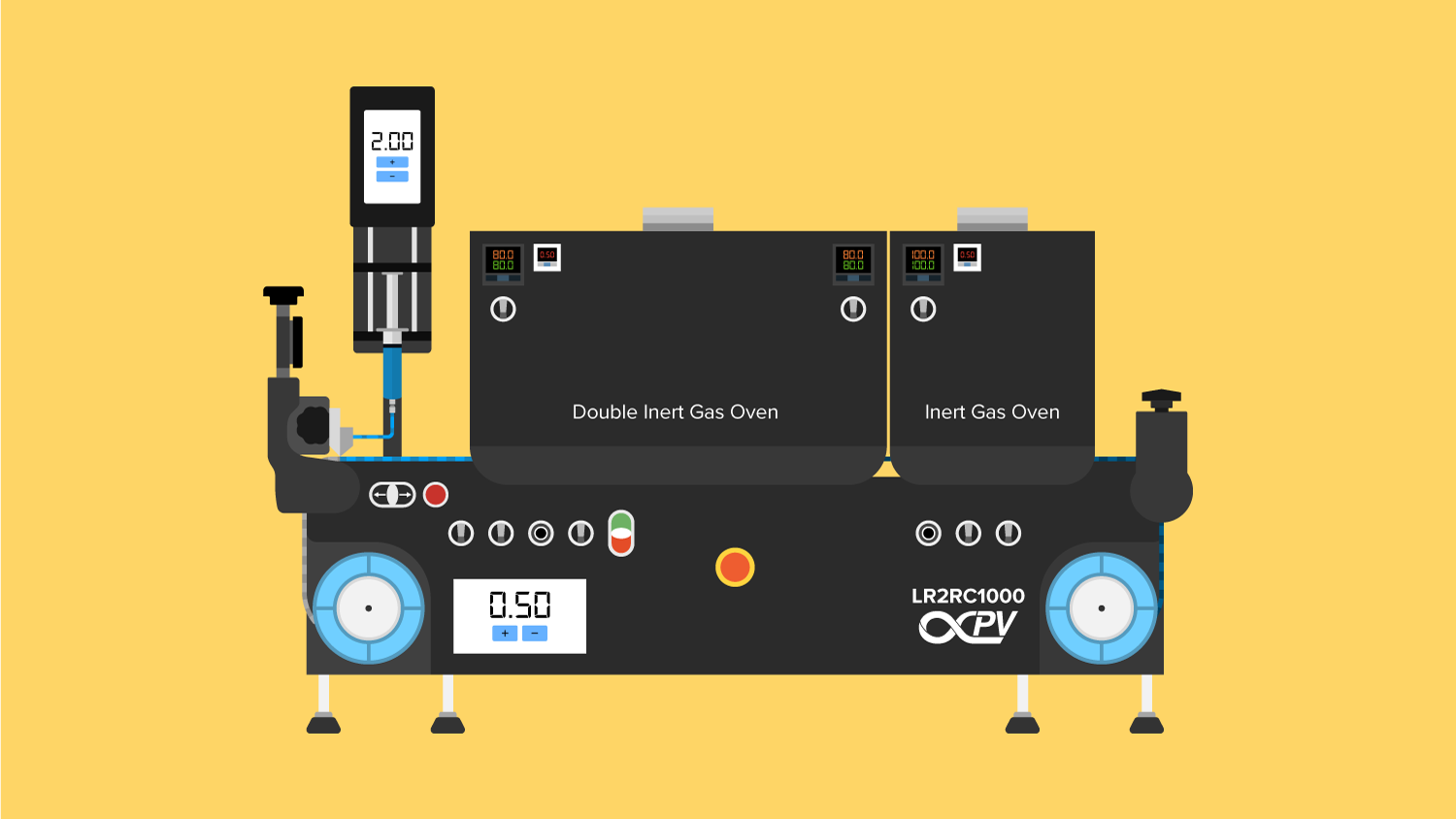

With its modular oven systems, the Laboratory Roll-to-Roll Coater secure efficient drying of the processed thin films using hot-air, inert gas, infrared or UV-curing.

Slurry Coating vs. Slot-die Coating

The slurry coater offers efficient coating with non-newtonian inks and inks with particles that may have a high density and a tendency to sediment through its simple technology. In contrast the slot-die coating provides a versatile and scalable solution. The slurry coater excels in uniform coating application for slurries, ideal for industries requiring consistency. On the other hand, slot-die coating offers flexibility and control, making it suitable for applications where varying thickness and materials are needed.

Broschüre herunterladen

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Video: Was ist der Laboratory Roll-to-Roll Coater?

Der Laboratory Roll-to-Roll Coater ist ein kompakter, hochpräziser Laborbeschichter, der die Verarbeitung von funktionellen Dünnschichten revolutioniert. Er bietet modulare Anpassungsmöglichkeiten für unterschiedliche Anforderungen, skalierbare Effizienz für die Produktion in kleinem Maßstab und ein benutzerfreundliches Design mit leicht abnehmbaren Komponenten. Ideal für Anwendungen wie Batterien, Brennstoffzellen und Solarzellen ermöglicht er Ihnen die Anpassung eines Systems, das perfekt auf Ihre Bedürfnisse zugeschnitten ist.

Ähnliche Produkte

Laboratory Roll-To-Roll Coater

Eine kompakte, hochpräzise Roll-to-Roll-Beschichtungsanlage für den Laborbereich, die die Art und Weise, wie dünne Funktionsschichten gedruckt und beschichtet werden, verändert.

Spritzenpumpen

Entdecken Sie die Präzision und Vielseitigkeit der infinityPV Spritzenpumpen, die für die nahtlose Integration in unsere hochmodernen Beschichtungs- und Druckanlagen entwickelt wurden.