Image 1 of 7

Image 1 of 7

Image 2 of 7

Image 2 of 7

Image 3 of 7

Image 3 of 7

Image 4 of 7

Image 4 of 7

Image 5 of 7

Image 5 of 7

Image 6 of 7

Image 6 of 7

Image 7 of 7

Image 7 of 7

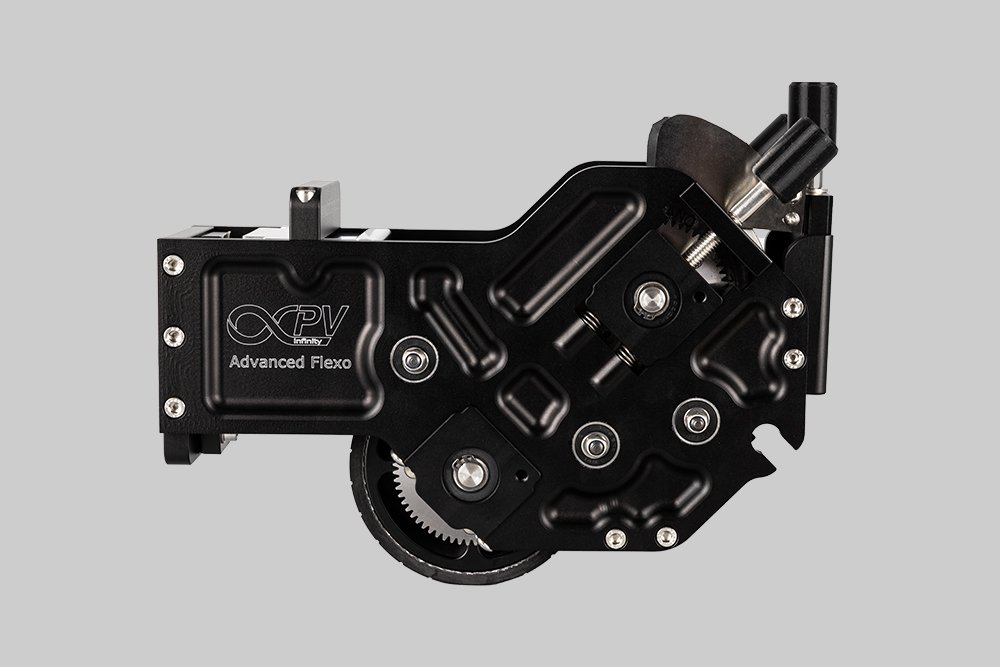

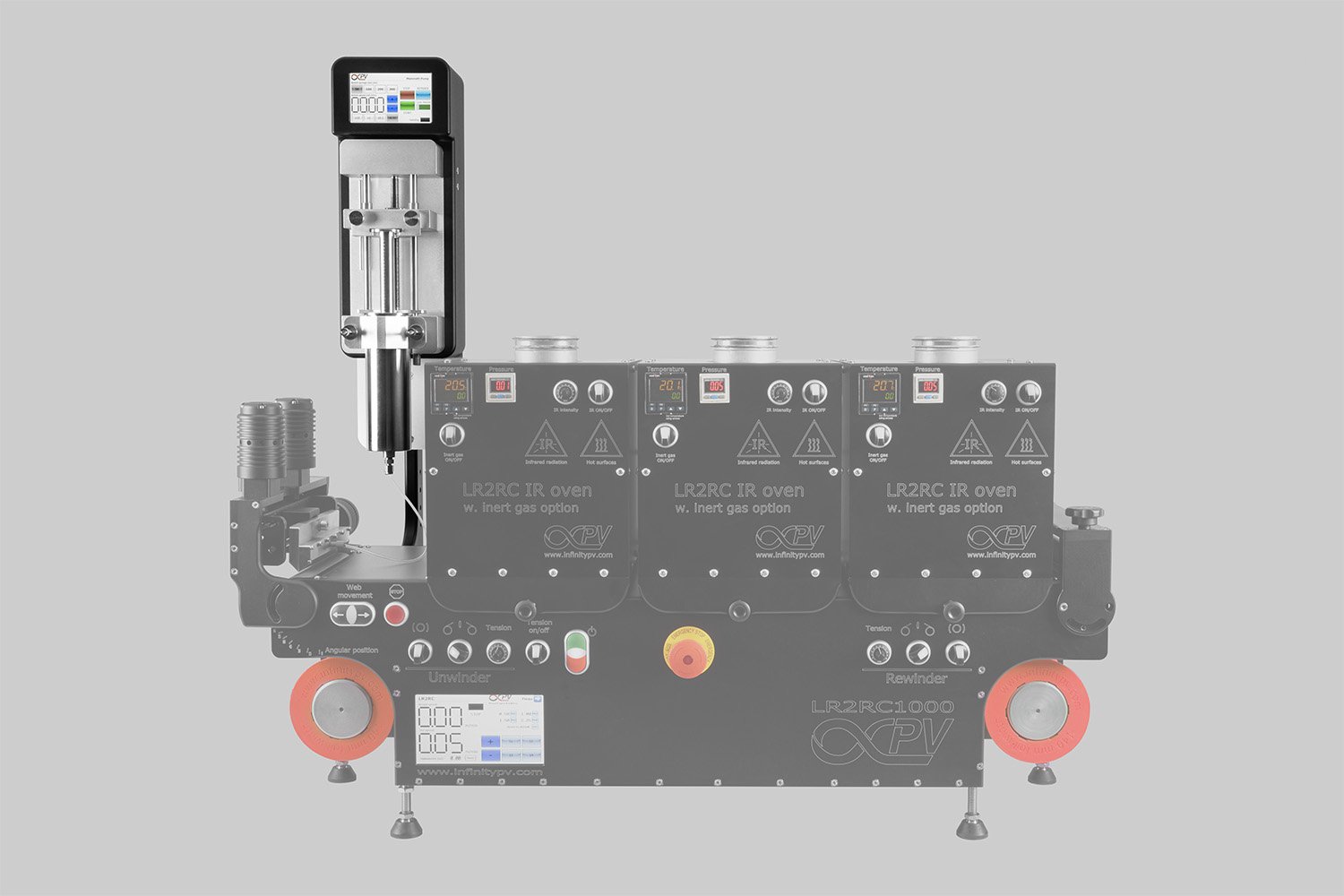

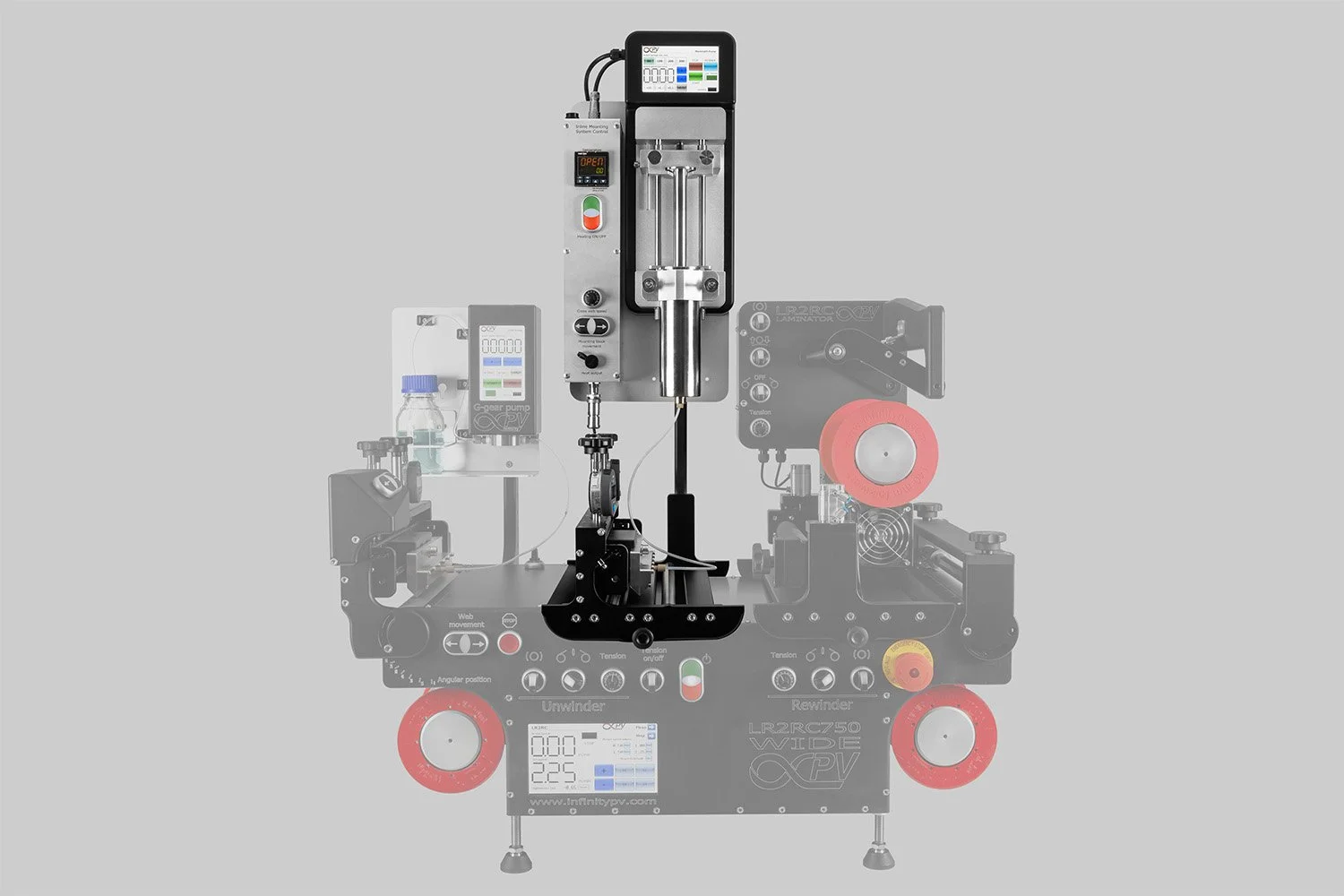

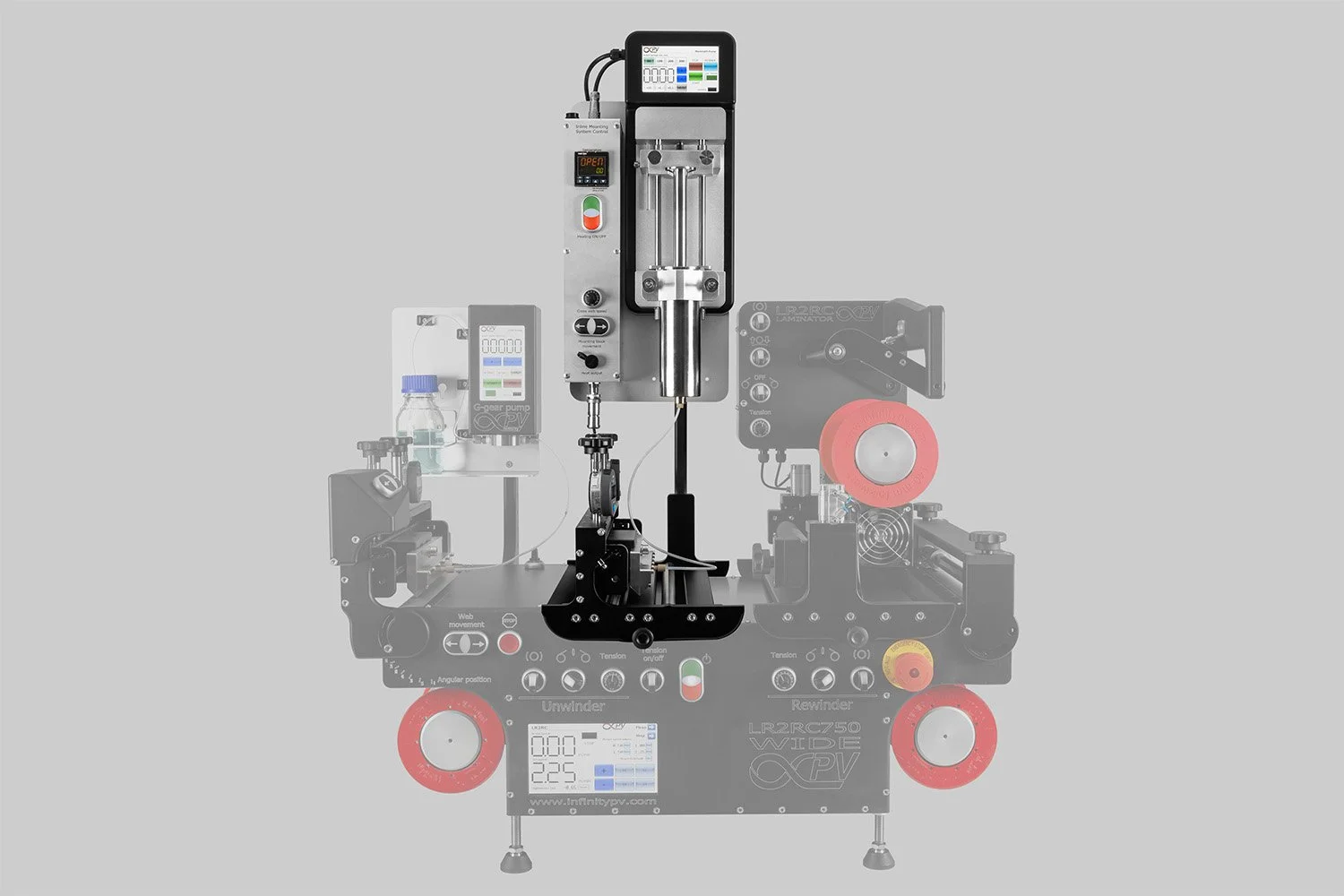

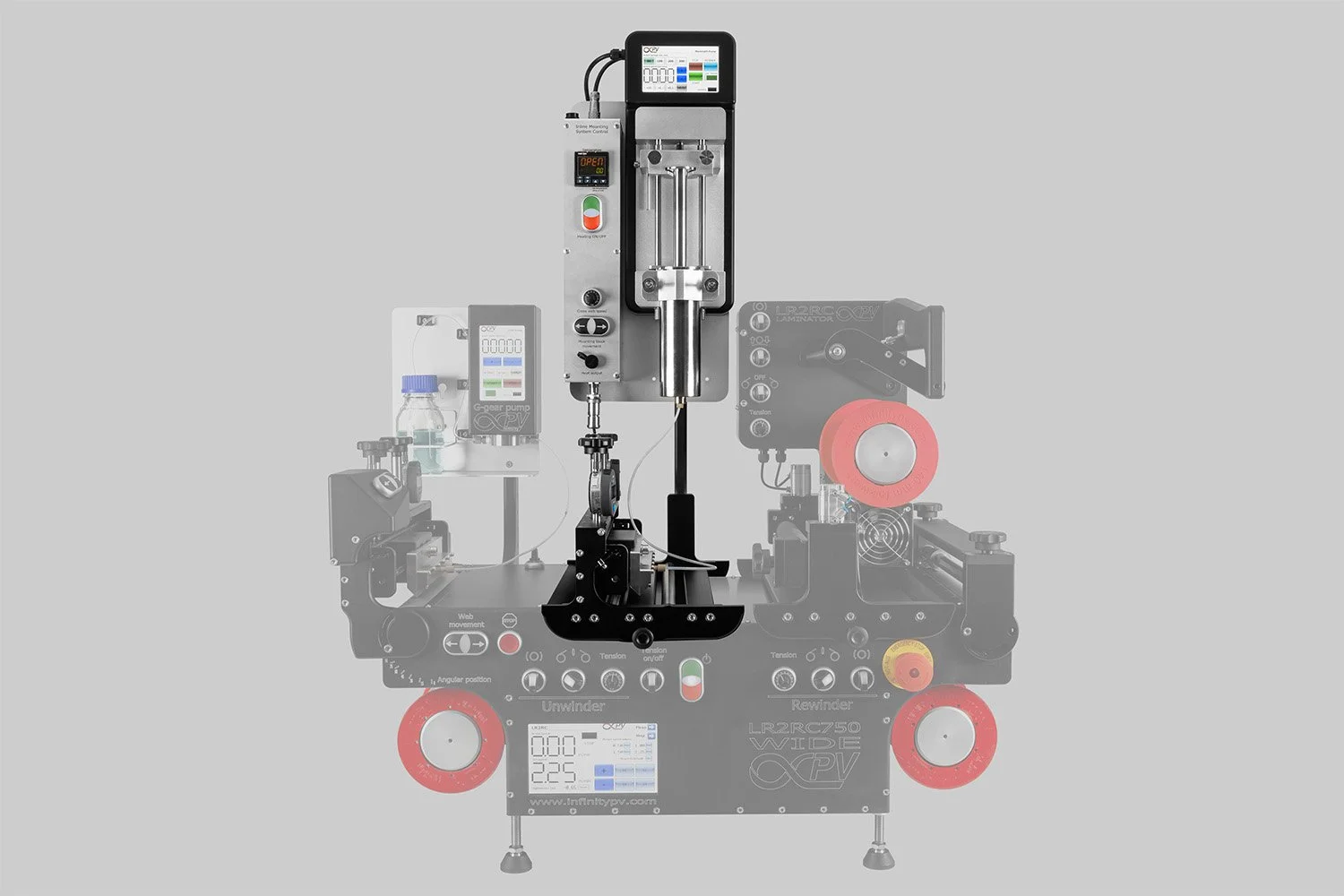

Inline-Halterung

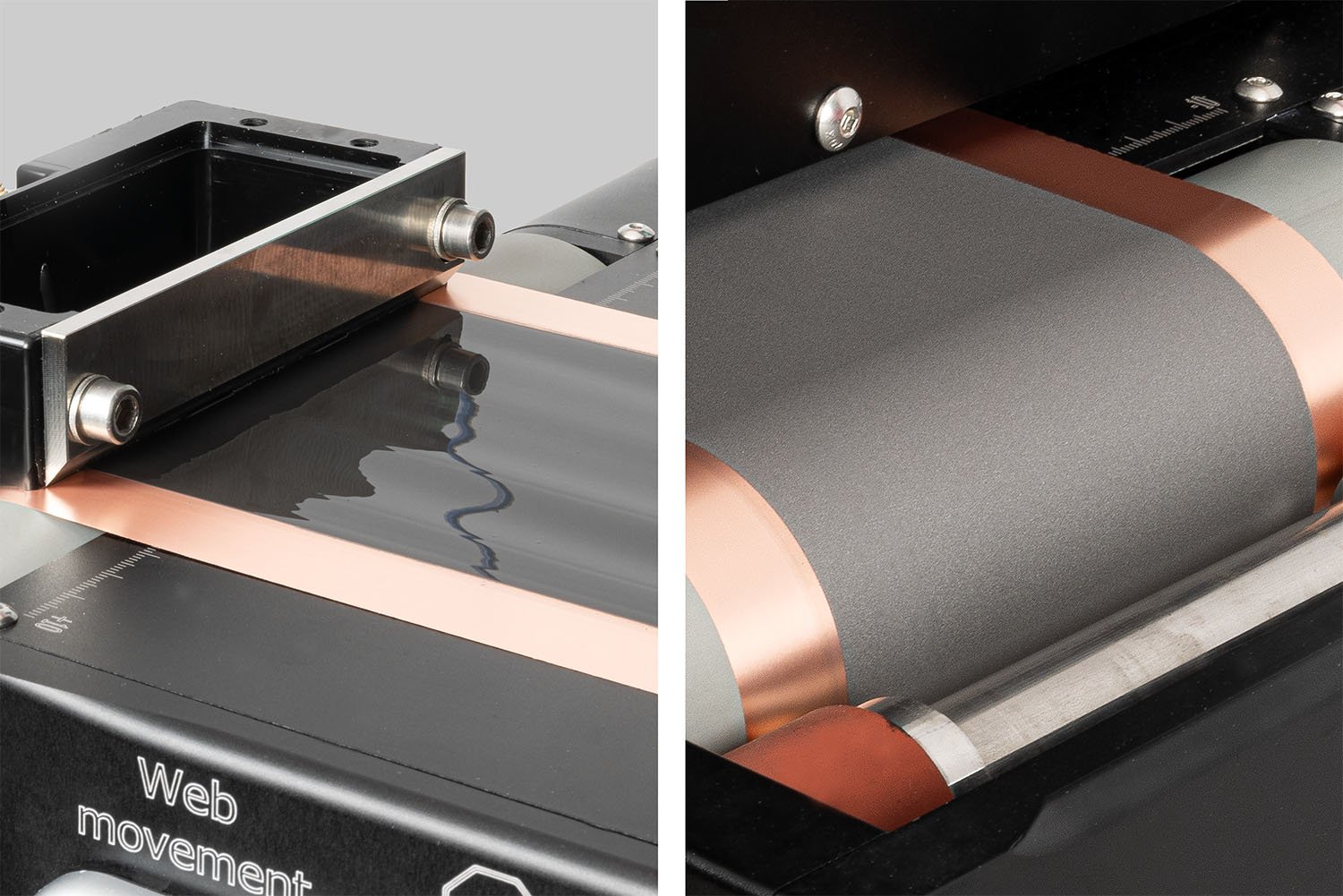

Die Inline-Montage kann überall auf der Bahn als zusätzliche Schlitzdüsenbeschichtungsstation für die Inline-Verarbeitung platziert werden, was eine flexible Anwendung der Rolle-zu-Rolle-Beschichtung ermöglicht.

Die Inline-Montage kann überall auf der Bahn als zusätzliche Schlitzdüsenbeschichtungsstation für die Inline-Verarbeitung platziert werden, was eine flexible Anwendung der Rolle-zu-Rolle-Beschichtung ermöglicht.

Die Inline-Montage kann überall auf der Bahn als zusätzliche Schlitzdüsenbeschichtungsstation für die Inline-Verarbeitung platziert werden, was eine flexible Anwendung der Rolle-zu-Rolle-Beschichtung ermöglicht.

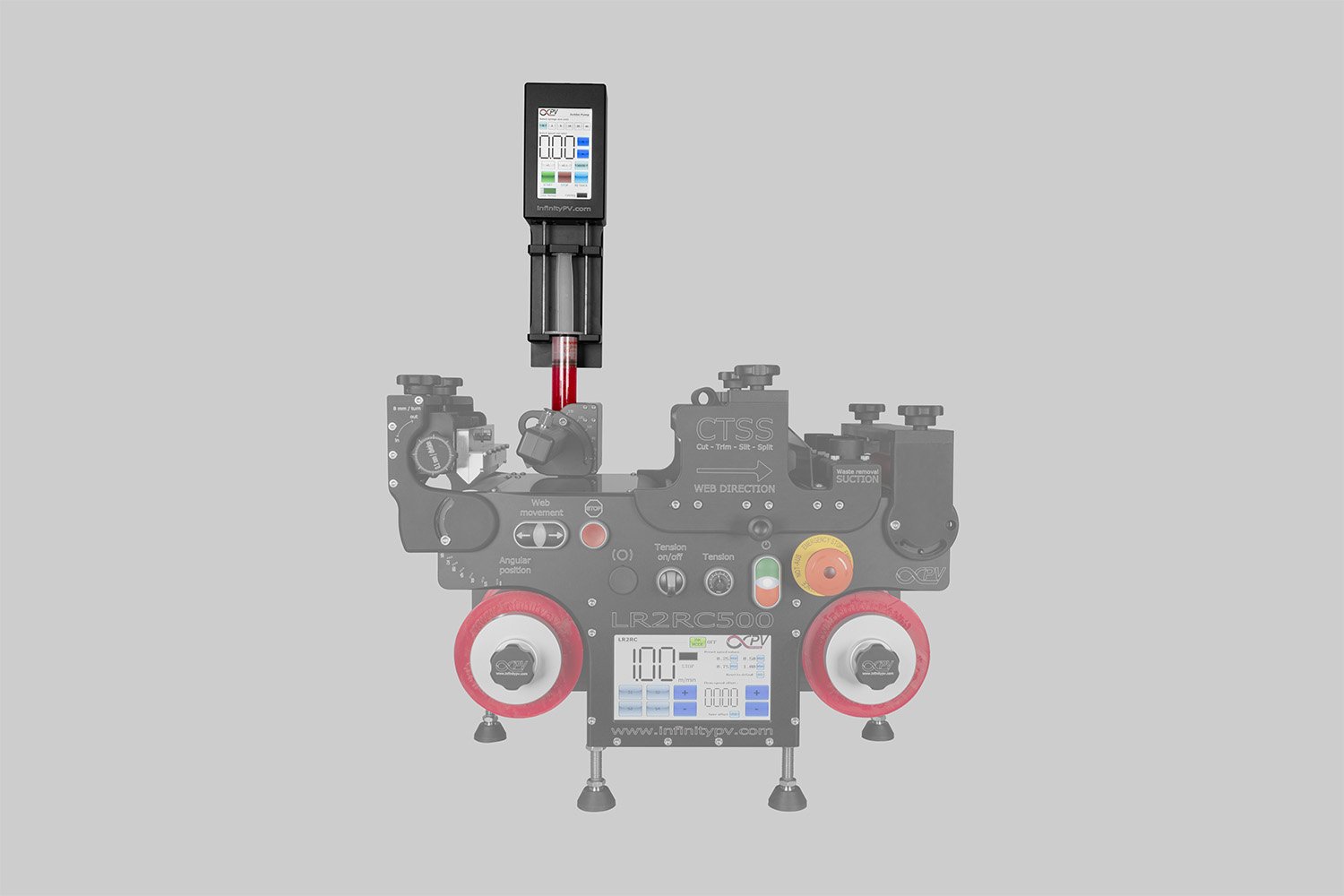

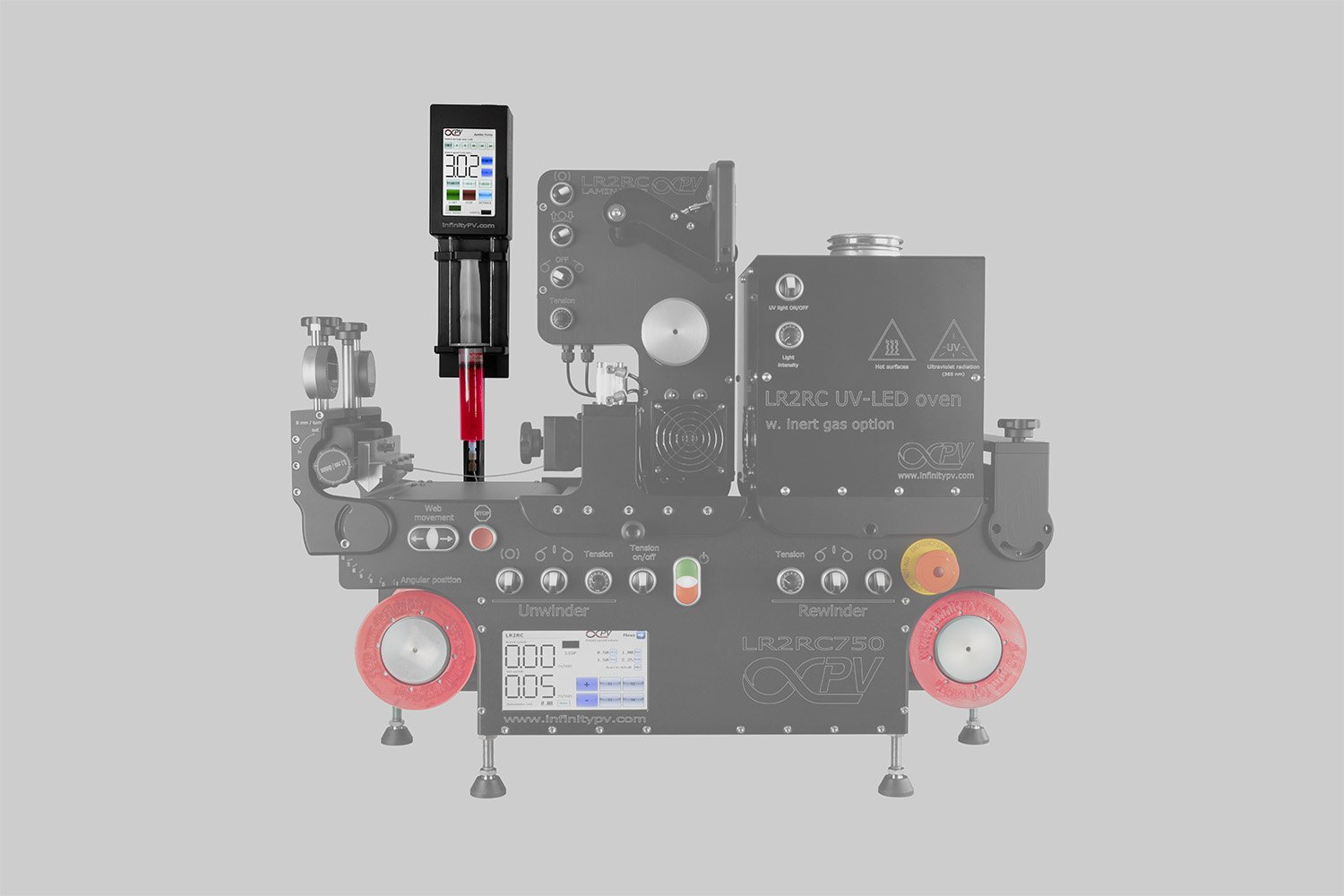

Why Use an Inline Mount?

Inline processing using slot-die coating refers to a continuous manufacturing approach where multiple layers or steps are integrated into a single, streamlined process. In this setup, the substrate moves through different coating and drying stations without stopping, allowing for sequential application of multiple layers in a continuous inline manner.

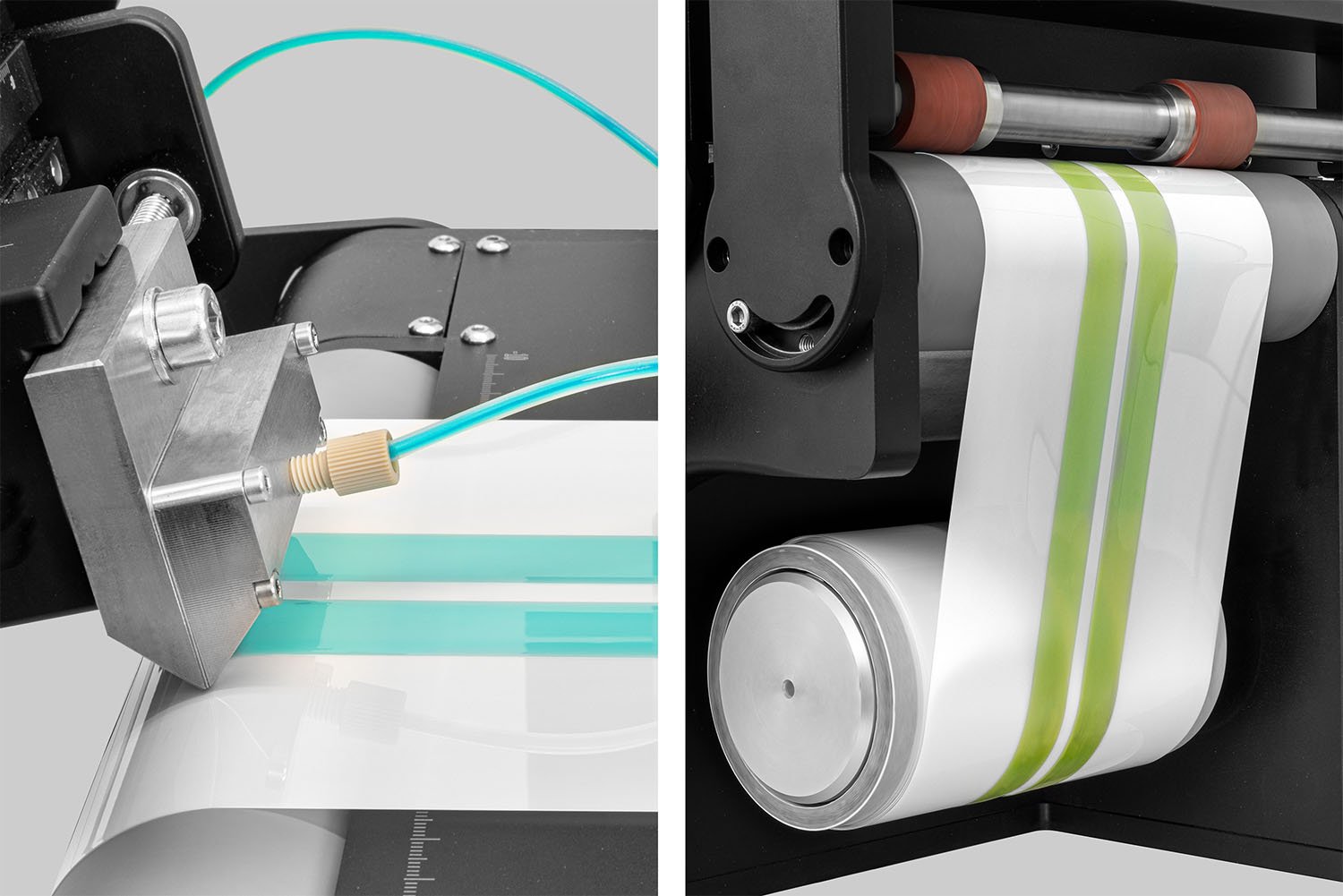

Wet-on-Wet Slot-die Coating

The Inline Mounting System also opens up for wet-on-wet slot-die coating. Wet-on-wet slot-die coating is a process where a new layer of wet material is deposited onto a substrate that already has a wet, underlying layer, without allowing the lower layer to dry or solidify beforehand. Wet-on-wet slot-die coating is useful in fabricating multilayer films in organic electronics, batteries, coatings, and other thin-film technologies where controlling the interface and layer formation dynamics is crucial.

The Inline Mounting System enables among others:

Drying or curing between layers: Typically, the underlying layer is dried or partially cured before the next layer is applied, ensuring each layer is solidified or stable before subsequent coating.

Wet-on-wet involves applying successive layers without drying or curing the underlying layer, all within a very short timeframe—usually in a single coating step.

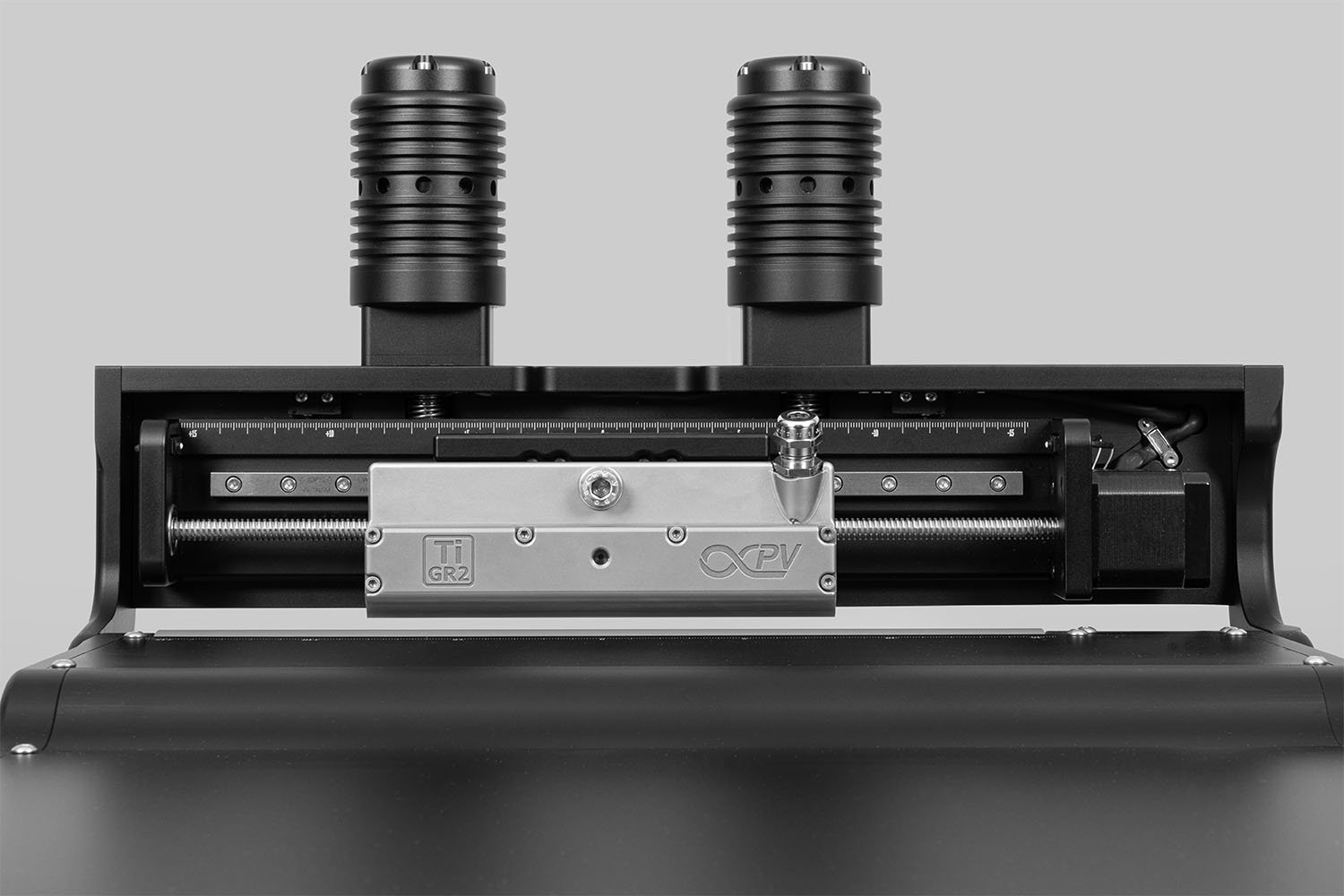

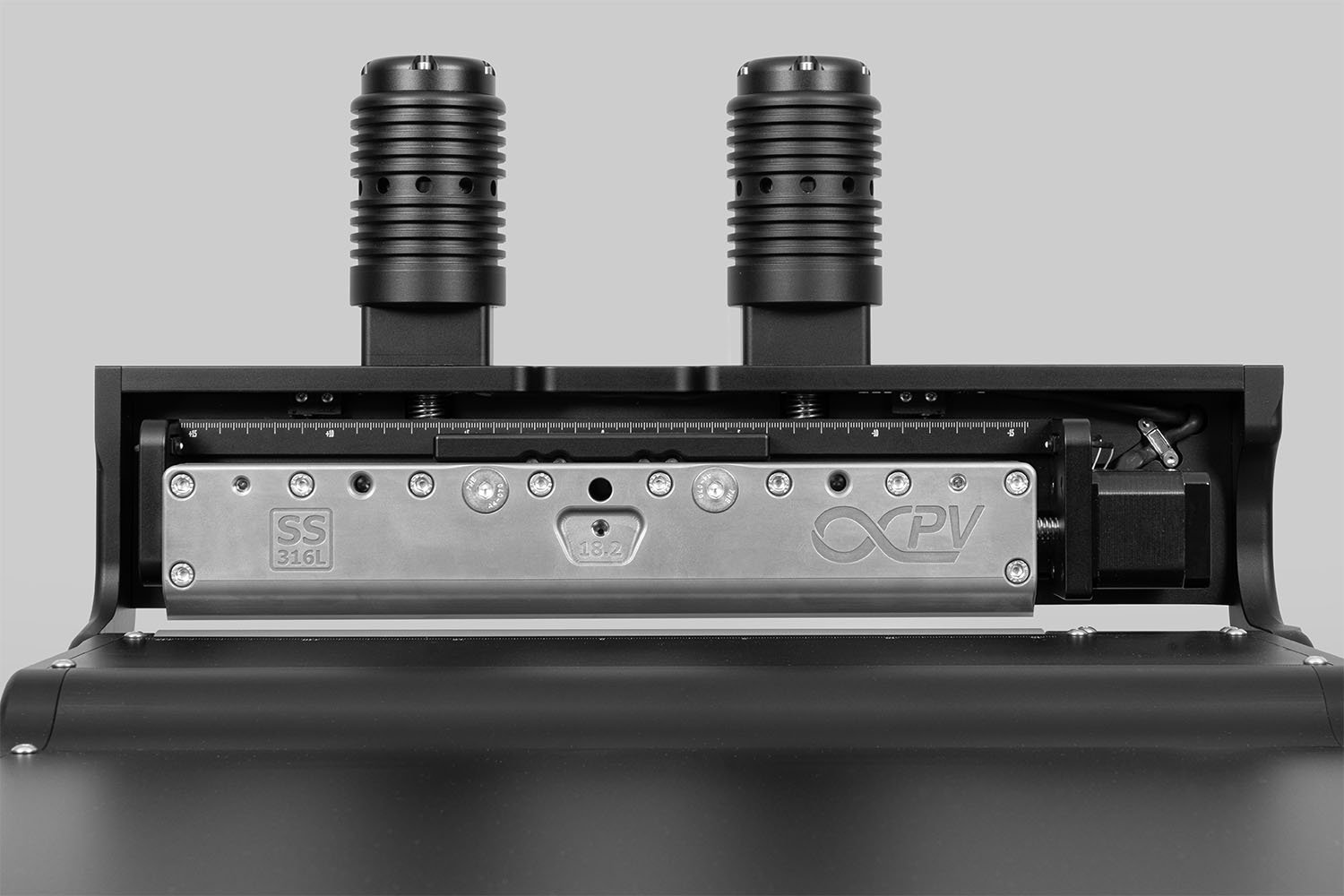

Inline Mount for the Laboratory Roll-to-Roll Coater

The Inline Mount is designed to seamlessly integrate with the Laboratory Roll-to-Roll Coater, a versatile and compact system for precise thin-film processing in lab and pilot-scale environments. Our modular components allow you to customize your coater for a wide range of applications including batteries, medtech, fuel cells, printed solar cells, sensors and more. Built for easy installation and interchangeability, these components help you optimize performance while maintaining flexibility and scalability.