Standard-Luftmesser

Provides versatile drying and quenching for thin films, with adjustable design for easy coating integration.

Revolutionize Your Lab With the Air Knife Standard

The air knife is a versatile tool designed for drying and rapid quenching of coated thin films, particularly beneficial for materials like perovskites, with compressed air or inert gas.

Its sleek design allows for close mounting to the coating station, while adjustable angles and distances ensure optimal drying or quenching without disrupting the coating process.

Compatible with the infinityPV Laboratory Roll-To-Roll Coater and Research Laboratory Coater, the Air Knife offers easy installation and adjustment using shims to customize the width and air blade gap, with included PET shims facilitating thickness adjustments.

Hauptmerkmale

Two Sizes Available: Air Blade Width Up to 140mm or 200mm

PET Shim Included: Thickness of 120μm

Angle Adjustment Mount Included

Air/Gas Inlet for 8mm Outer Diameter Air Hose Included

Easy Assembly and Disassembly

Constructed with Anodized Aluminum

Compatible with the Laboratory Roll-to-Roll Coater and Research Laboratory Coater

Setups Featuring the Air Knife Standard

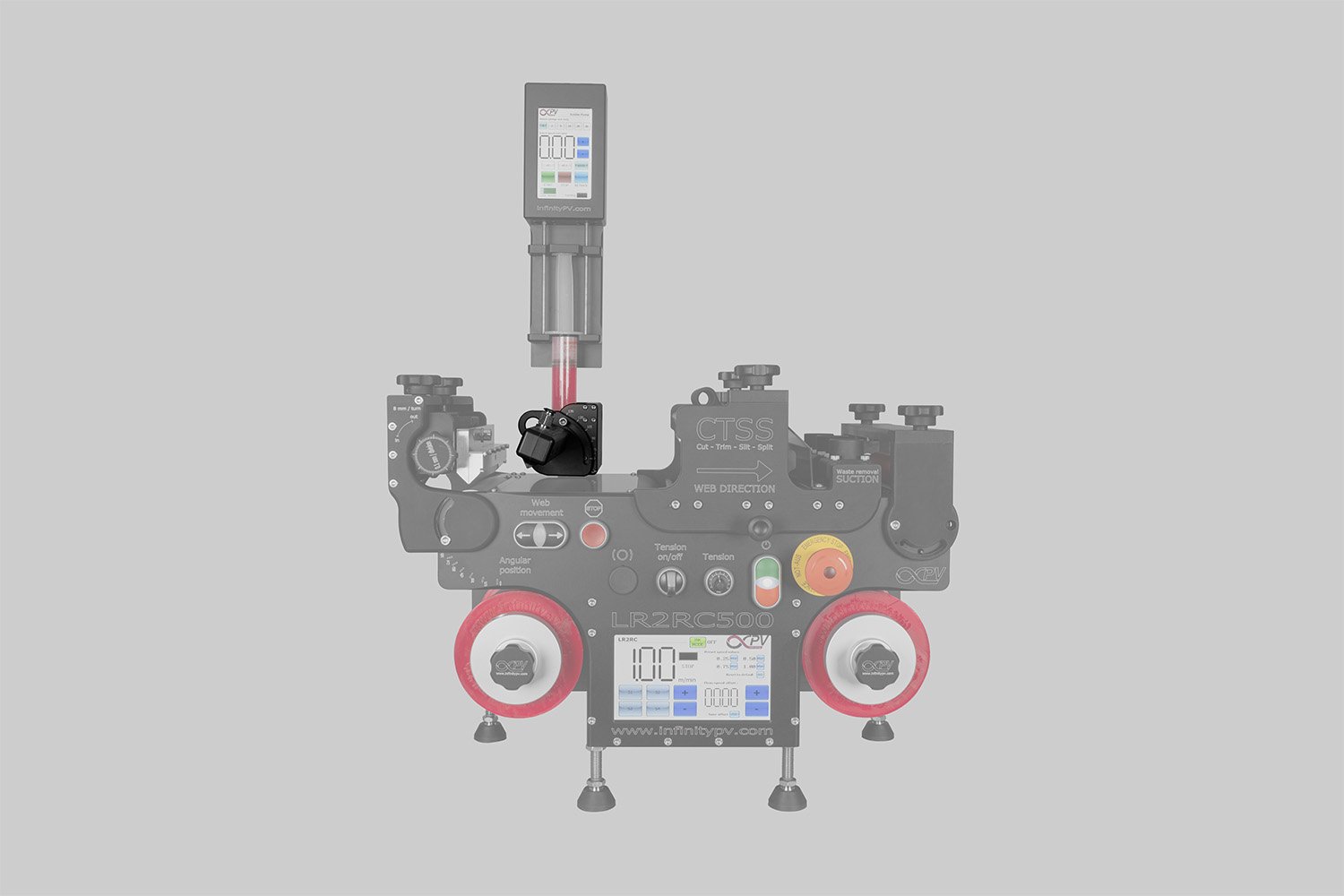

The Air Knife Standard mounted on an LR2RC500 platform featuring a Simple Mounting System, stainless steel Slot-die Head, Jumbo Syringe Pump, Roll-to-Roll Laminator and Nip Roller.

The Air Knife Standard mounted on an LR2RC500 platform featuring a Simple Mounting System, Simple Flexo Roller, Jumbo Syringe Pump, IR Oven and a Nip Roller.

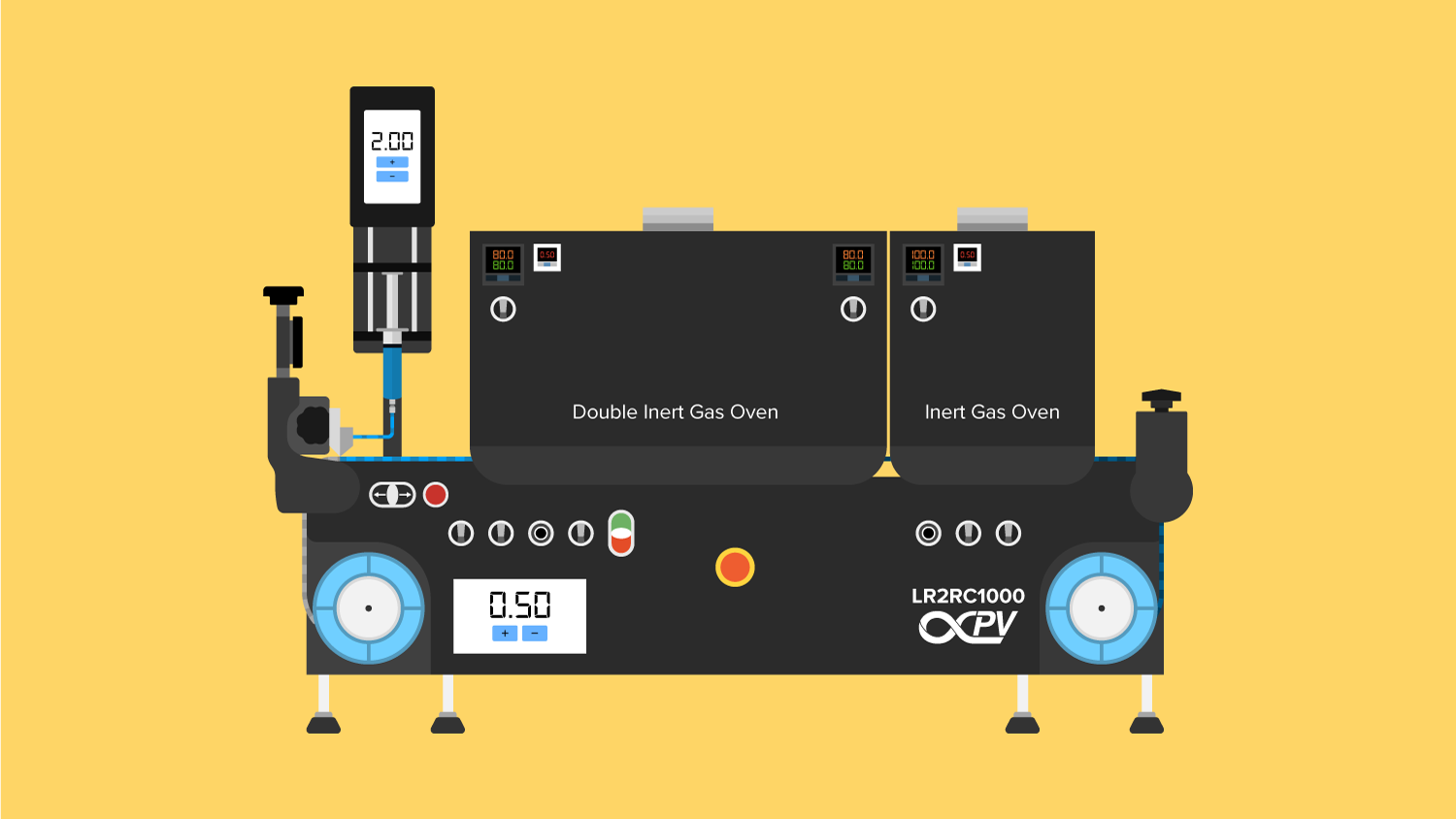

The Air Knife Standard mounted on an LR2RC1000 platform featuring a Advanced Mounting System, PEEK Slot-die Head, Jumbo Syringe Pump, two IR Ovens and a Nip Roller.

The Air Knife Standard mounted on an LR2RC1500 platform featuring an Advanced Mounting System, stainless steel Slot-die Head, Jumbo Syringe Pump, Roll-to-Roll Laminator, Double Inert Gas Ovens, Combo Oven, Knife Cutter and a Nip Roller.

Upgrade to the Air Knife Pro

The Air Knife Pro is the perfect choice If you need precise control over the drying or quenching of coated thin films. With micrometer screws and a digital display, the Pro model allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

Video: Was ist der Laboratory Roll-to-Roll Coater?

Die Labor-Roll-to-Roll-Beschichtungsanlage ist eine kompakte, hochpräzise Laborbeschichtungsanlage, die die Verarbeitung dünner Funktionsschichten revolutioniert. Sie bietet modulare Anpassungsmöglichkeiten für unterschiedliche Anforderungen, skalierbare Effizienz für die Produktion in kleinem Maßstab und ein benutzerfreundliches Design mit leicht abnehmbaren Komponenten. Ideal für Anwendungen wie Batterien, Brennstoffzellen und Solarzellen ermöglicht sie Ihnen die Anpassung eines Systems, das perfekt auf Ihre Bedürfnisse zugeschnitten ist.

Broschüre herunterladen

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Wahrscheinlich der kompakteste R2R-Schlitzdüsenbeschichter der Welt

Das LR2RC500-Bundle ist eine kompakte, vollständig integrierte Rolle-zu-Rolle-Beschichtungsplattform für Labore, komplett mit einem fortschrittlichen Montagesystem, eloxierten Walzen, einer Jumbo-Spritzenpumpe, einem 65-mm-Edelstahl-Schlitzdüsenkopf und einem Infrarot-Ofensystem, das unübertroffene Präzision und Skalierbarkeit bietet.